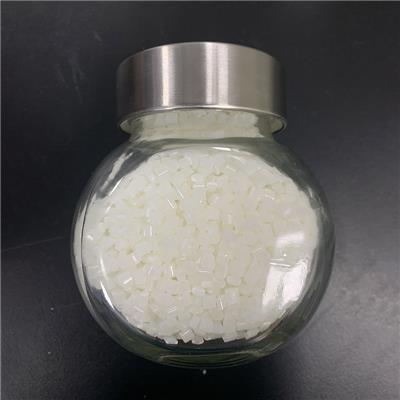

High MFI Impact Modifier for PA6/PA66 ST-H4100

2023/4/20

![]()

Product Profile

This impact modifier for nylon contains maleic anhydride active functional groups. Used in engineering plastics like PA6, PA66, etc. It has reaction activity with amine end group of nylon resin. By this way, the interface strength between impact modifier and nylon resin will be increased and the nylon system can get good mechanical property. The MFI of ST-H4100 is much higher than traditional impact modifiers, which meansit hasless effect to nylon’s flowability.

Specification

|

Item

|

Value

|

|

Density

(23℃ g/cm³)

|

0.89 |

|

Melt Index

(190℃,2.16kg g/10min)

|

11-18 |

|

MAH Content

(% )

|

0.3-0.5 |

Recommended Dosage

For common GF reinforced or flame-retardant PA6 or PA66: 3-6%.

For super toughening PA6 or PA66: 15-20%.

Recommended Processing

For PA6,processing temperature: 235-245℃, screw speed: 250-600rpm.

For PA66,processing temperature: 275-285℃, screw speed: 250-600rpm.

Package & Storage

25kg/package, transported as common chemicals. Keep in dry, cool place. Storage

temperature not exceeds 45℃. To prevent cross-linking, please clean the twinscrew

immediately after use.

Anhui Star-Better New Material Technology Co., Ltd. 版权所有 皖ICP备2023006323号-1 Disclaimer